Products 2

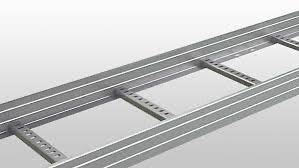

Cable Tray Installation Methods

Ceiling Mounted

Floor Mounted

Wall Mounted Horizontally

Wall Mounted Vertically

Cable tray manufacturing raw materials

1. Electrogalvanized steel cable

2. Pre-galvanized steel cable trays

3. Hot dip galvanized steel cable trays

4. Aluminum cable tray

5. Electrostatic stainless steel cable tray.

6. Fiberglass cable tray

Types and dimensions of cable tray sides

Types of side heights

Straight Return Flange

Inside Return Flange

Outside C-Type Inside

C-Type Outside Return Flange Straight Return Flange Inside Outside

C-Type Inside

C-Type Outside

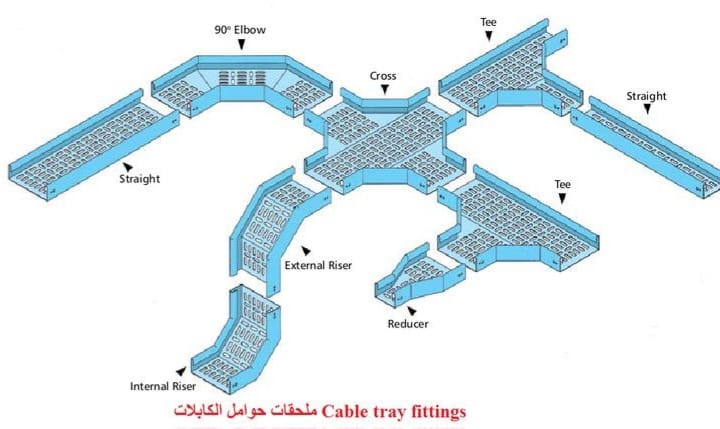

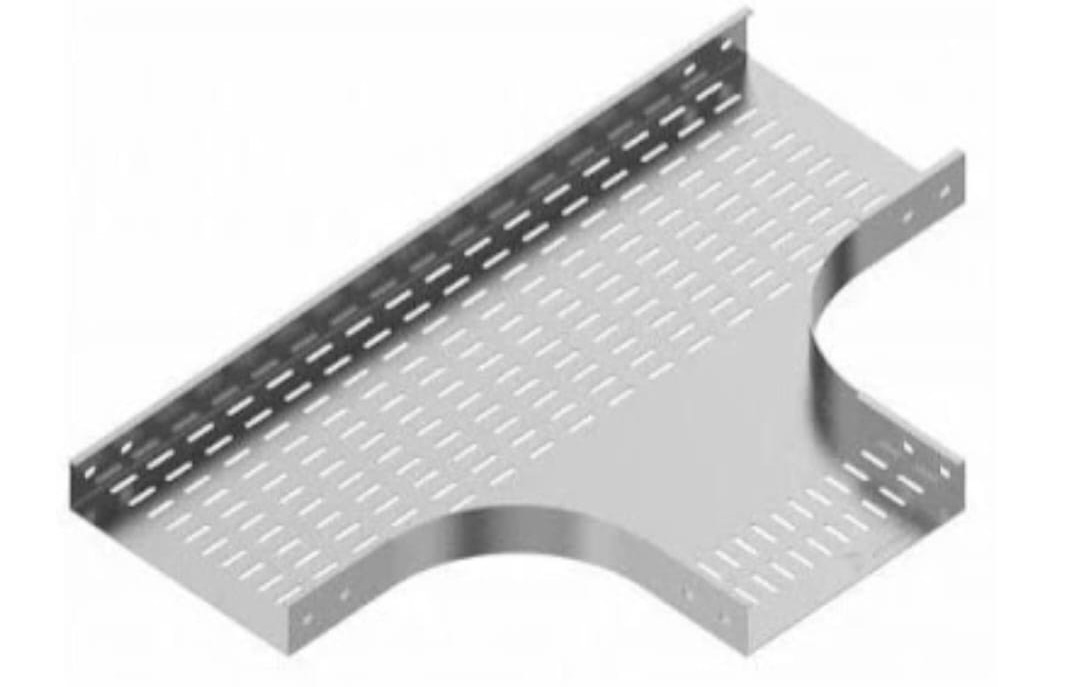

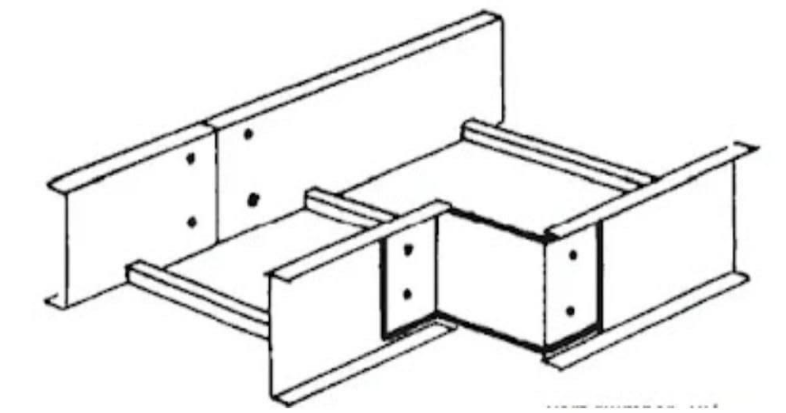

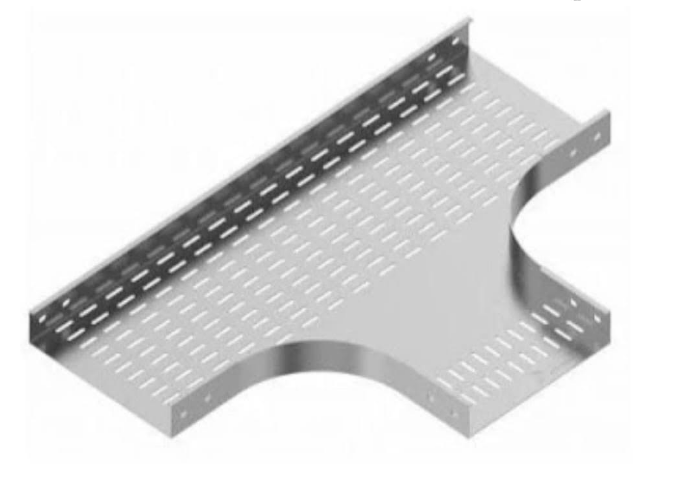

Tee Connection

It is used to connect three cable trays in three directions, with a 90 degree angle between each tray and the next in the same horizontal level

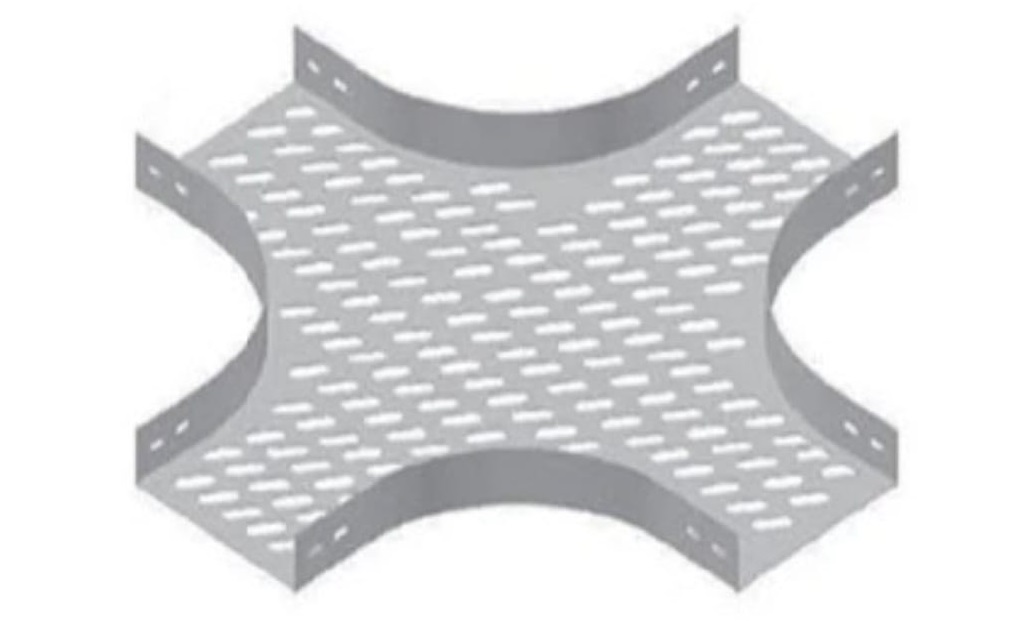

Cross connection

It is used to connect four cable trays in four directions with a 90 degree angle between each tray in the same horizontal level

Riser Bend

There are two types: Internal Riser: It is used to change the direction of the cable tray from the lower level to the higher level. External Riser: It is used to change the direction of the cable tray from the upper level to the lower level

offset reducing connector

Used to connect cable trays of different widths.

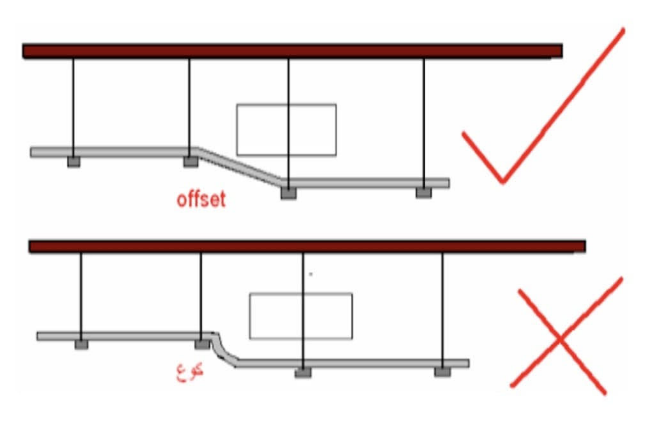

Levels

In the event of descending from one level to another in the horizontal cable tray, such as facing an air conditioning duct, for example, in the cable tray path, and having to descend from under it, an offset is made straight between the two levels instead of an elbow, as in the following figure: offset elbow X

Cable tray size

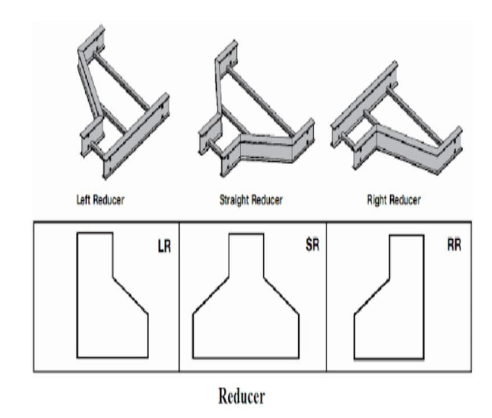

When the cable tray size differs from a certain point due to a cable or cables falling on the panel, we place a Reducer to change the size of the cable tray (for example, from 600 mm to 300 mm). It has three types: Left Reducer Straight Reducer Right Reducer LR SR RR Reducer – It is preferable to place the type of Reducer according to the direction of the cable or cables falling (Left of Right). If the falling is from both sides, we use the straight type

Cable tray thickness

The thickness of the cable tray is chosen based on the weight of the cables that will be placed on the tray in addition to the weight of the tray itself. Cable trays are available in standard thicknesses as follows: 1, 1.25, 1.5, 2 mm. The thickness of the cable trays is expressed in another way according to the thickness of the tray as follows: Light duty – medium duty – heavy duty – very heavy duty.

1) Elbow / Bend: There are two types:

(45) Horizontal elbow: used to change the direction of the cable tray at a 45-degree.

(90) Horizontal elbow: used to change the direction of the cable tray at a 90-degree.

Vertical elbow: It is used to change the direction of the cable tray from one horizontal level to another horizontal level. It is divided into two types:

inside vertical elbow: used to change the direction of the cable tray from one horizontal level to another horizontal level to upward direction.

outside vertical elbow: used to change the direction of the cable tray from level

Hot dip galvanized steel where in this case the cable tray panels are immersed after manufacturing or shaping in a bath of molten zinc.

The resulting galvanizing layer is thicker than that produced in the previous case, and this manufacturing method is suitable for outdoor uses

Electrogalvanized steel cable tray: In this type, a layer of zinc is deposited on the surfaces of the cable tray through electrolysis in a bath of zinc salts. The bath is made up of zinc acids or bases. The anode is zinc and the cathode is the pieces of cable trays to be painted. After the painting process is completed, the produced cable trays are painted with a layer of chromium to increase their protective capacity

Pre-galvanized steel: In this case, the cable tray panels are passed over molten zinc before they are formed. This manufacturing method is suitable for indoor uses

Stainless steel: The cable tray in this case is resistant to rust, chemical reactions, high temperatures, and also deflection. This type is widely used in marine sites, petroleum sites, chemical plants, etc.

Cable Tray Width: The width of the cable tray is selected based on the total diameter of the cables to be placed on the tray, in addition to the spacing between the cables. Cable trays are available in standard widths as follows: 50, 100, 150, 200, 250, 300, 400, 600, 700, and 900. Cable Tray Height: The height of the cable tray is selected based on the largest diameter of the cables to be carried on the tray. Cable trays are available in standard heights as follows: 50, 75, 100, and 25 mm

Aluminum is lightweight, easy to install, low maintenance, and rust-resistant. Since aluminum is a non-magnetic material, it significantly reduces electrical losses from cables placed on the rack